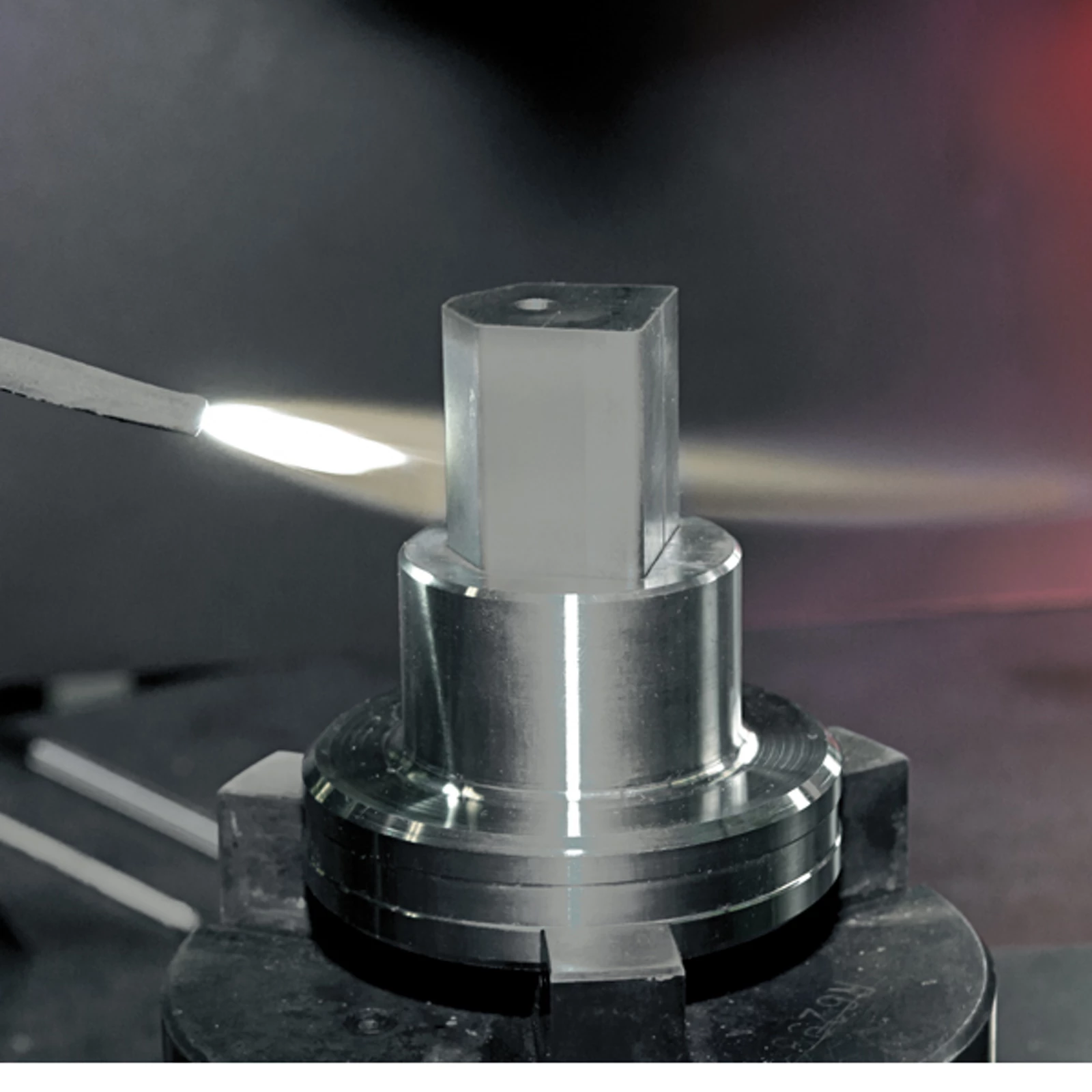

When joining cemented carbide with other materials its special properties must be taken into account:

- Carbide is a brittle material

- Edges have to be protected (use radii, chamfers etc.)

- Fits and guides need to be adapted to the material properties (angularity, clearances, centring etc.)

- The combination of different materials almost always causes stress close to the joint because of the variation in rigidity