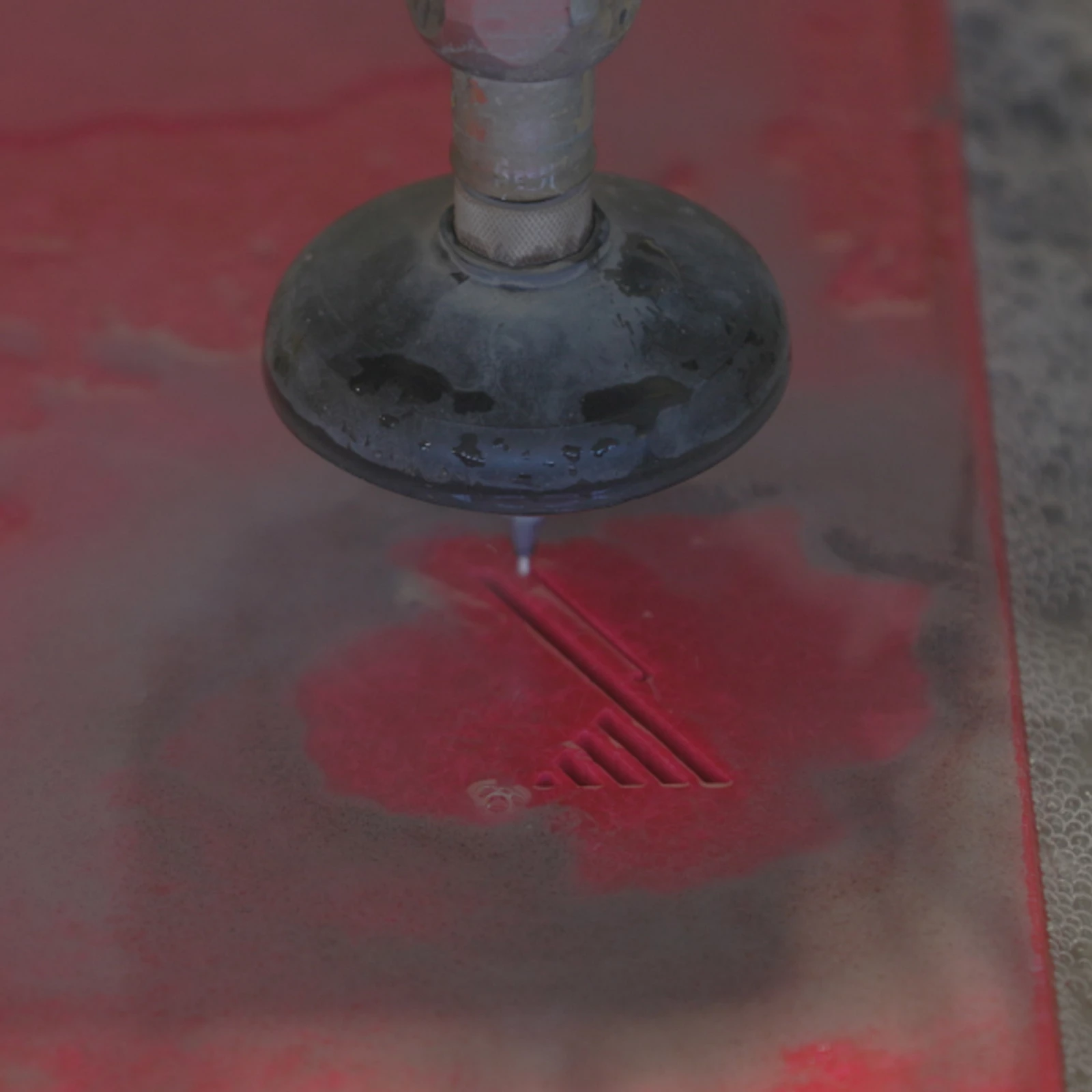

Improved efficiency

Our three distinct HyproJET product lines offer you the best price-performance ratio for your applications. The focusing tubes are suitable for all modern cutting head systems and support automatic centering during mounting. Close-hole tolerances, perfect grind, and concentricity guarantee precise working results.

As CERATIZIT takes care of all process phases with the carbide powder to the ready-to-use solution, we can always offer you top-class product quality, precision, and the best performance.