Together with our business partners, we develop new products and applications for various markets within the food and beverage processing industry. Just contact us and we will help you find the best solution for your challenge!

Cocoa industry

For cocoa processing, we manufacture a variety of styles and types of cocoa crusher blades, mixing arms, or rotor pins made from our corrosion-resistant cemented carbide grades.

Coffee industry

Our carbide solutions are also suitable for use in coffee production: we supply coffee milling disks for industrial espresso machines as well as spray nozzles, swirl chambers, and orifice inserts to improve the performance of the spray drying and agglomeration process.

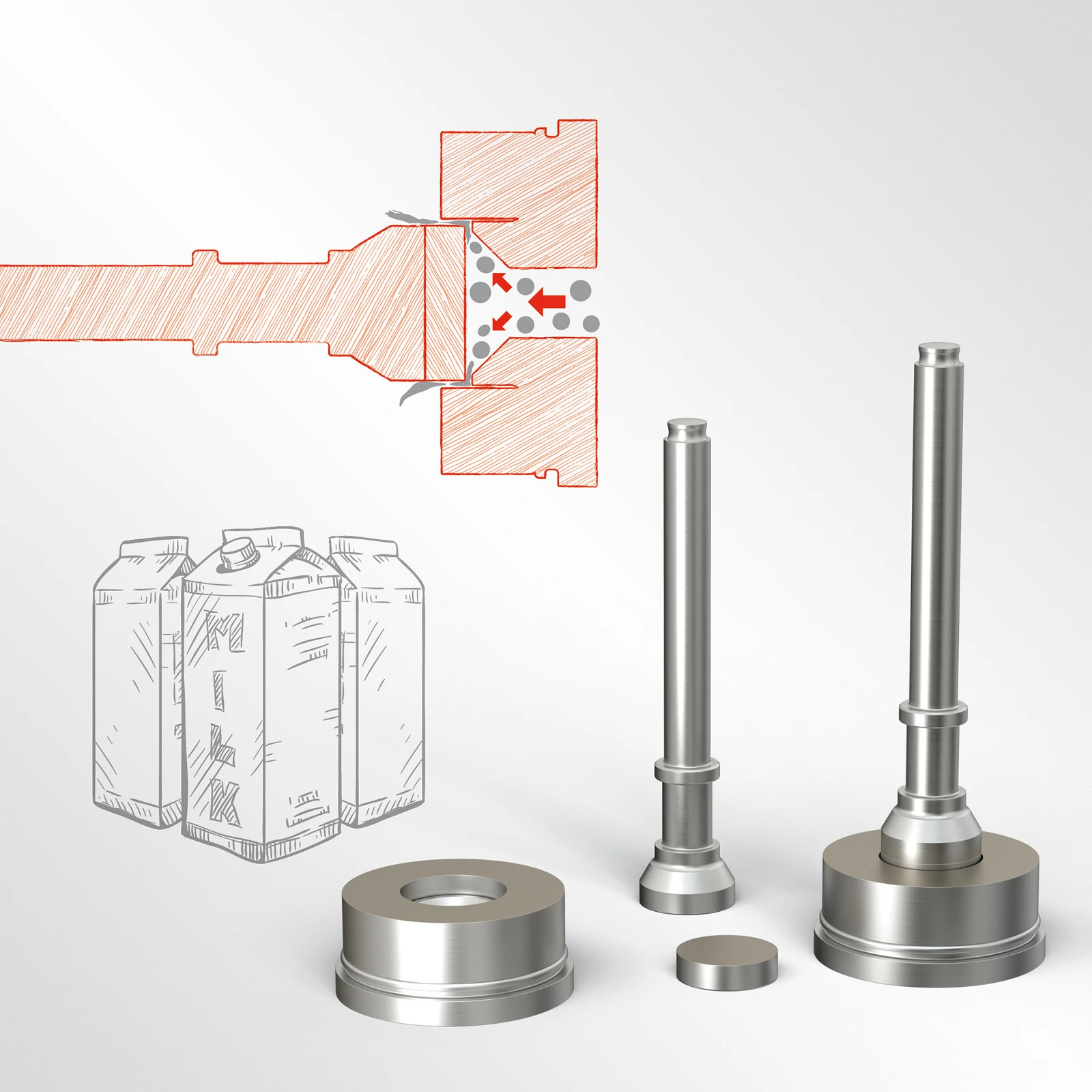

Dairy products

Where liquids are homogenised, milk for example, carbide and steel-carbide composite components in pump and valve systems are never far away. Our abrasion- and corrosion-resistant products such as pistons and valve seats withstand the highest pressures and temperatures.

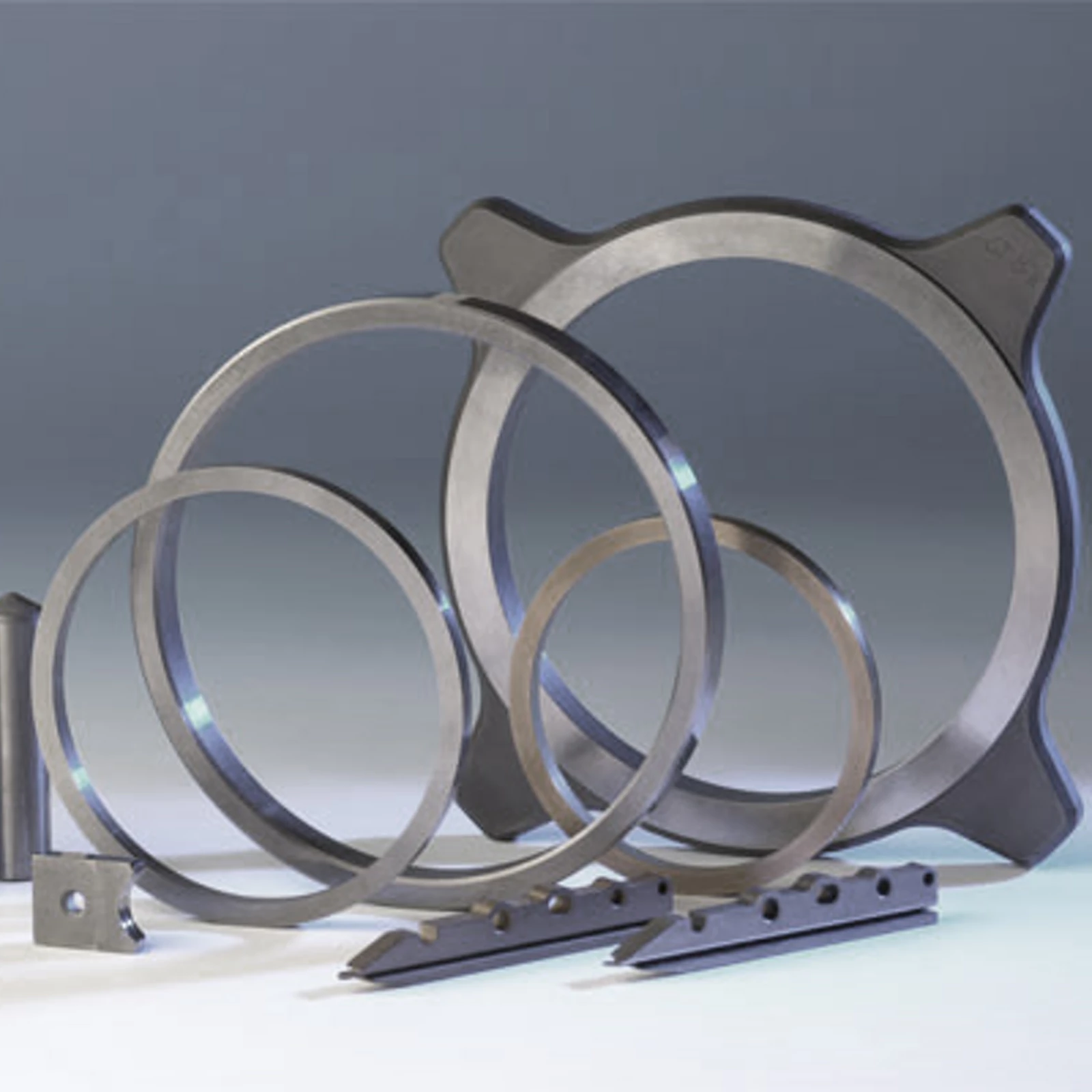

The hyperbaric pasteurisation process (HPP) to increase the shelf life of different kinds of food also requires very precise and wear-resistant parts, such as sealing rings and plungers.

Frozen products

As the freezing methods used to preserve foods become more sophisticated, so do their manufacturing processes. We offer tough carbide products which are up to the challenge of processing frozen goods with marginal wear.

Meat industry

When cutting or skinning meat, thin carbide blades are used – for instance, as tips in circular saws or as perforated dies in meat grinders; carbide guiderails for band saws used to divide large pieces and bones also fall in this category.

Beverage and liquid foods industry

Extruders, decanters, and separators are used in many application fields and also play a major role within the food processing industry. Used for mixing and phase separation, the processing systems require different parts with high abrasive and corrosive resistance: this is where CERATIZIT comes into play with bushings, wear liners, nozzles, and tiles.

Pet food industry

When we consider food as a whole, we also take pet food into account. For instance, producers of pet food need wear-resistant mixing elements. For the further production of pellets, similar to pasta processing, we provide perforated dies and high-precision knives, for example.