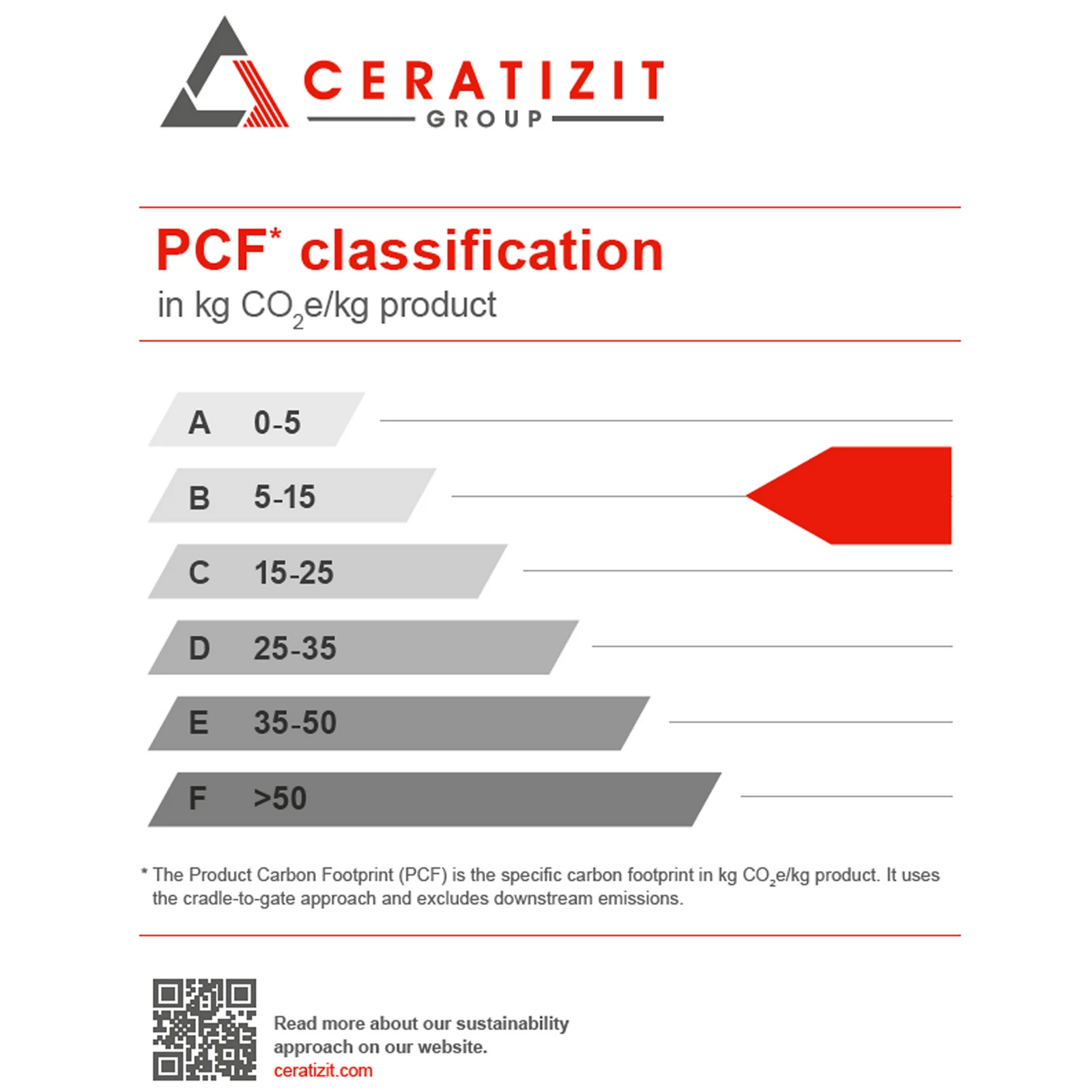

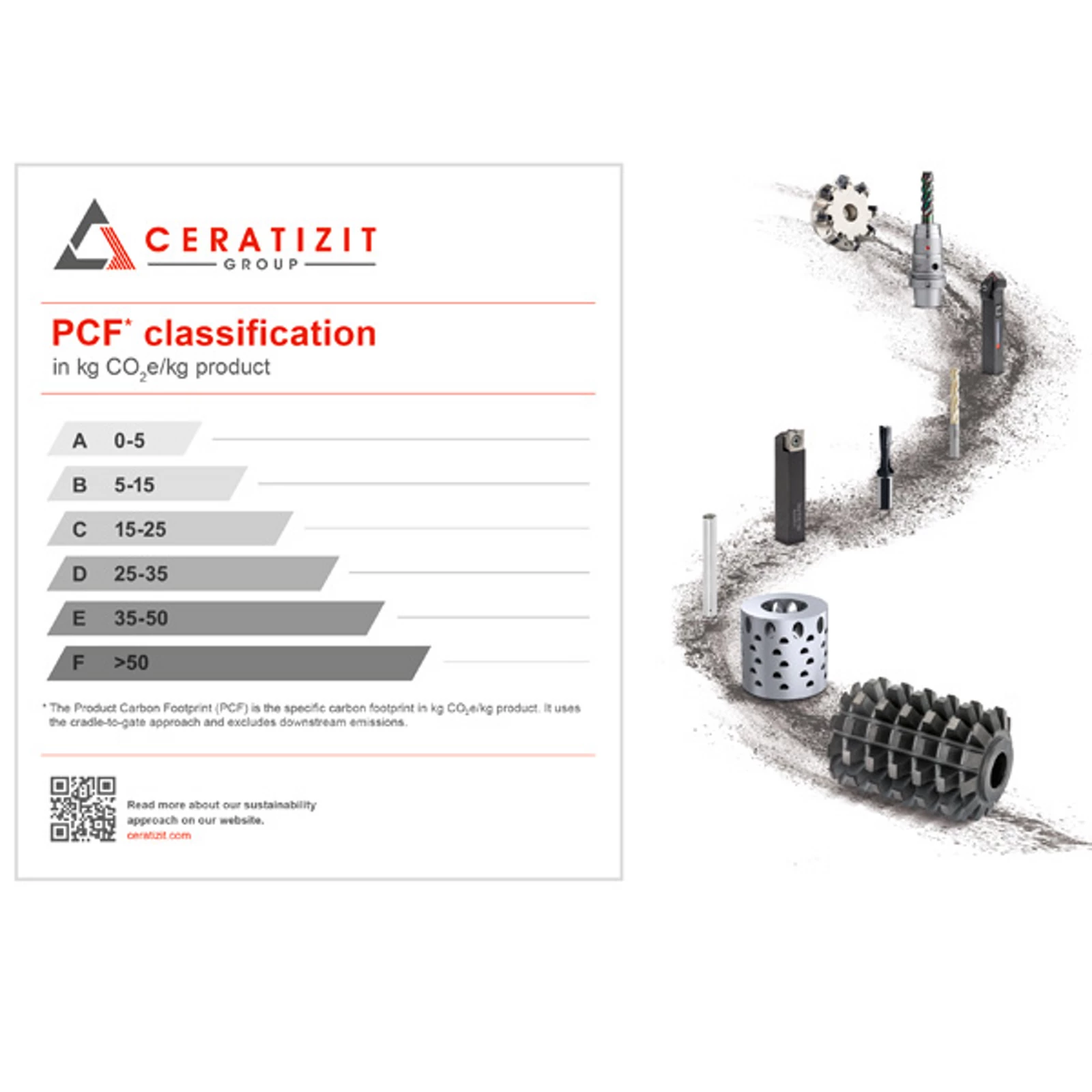

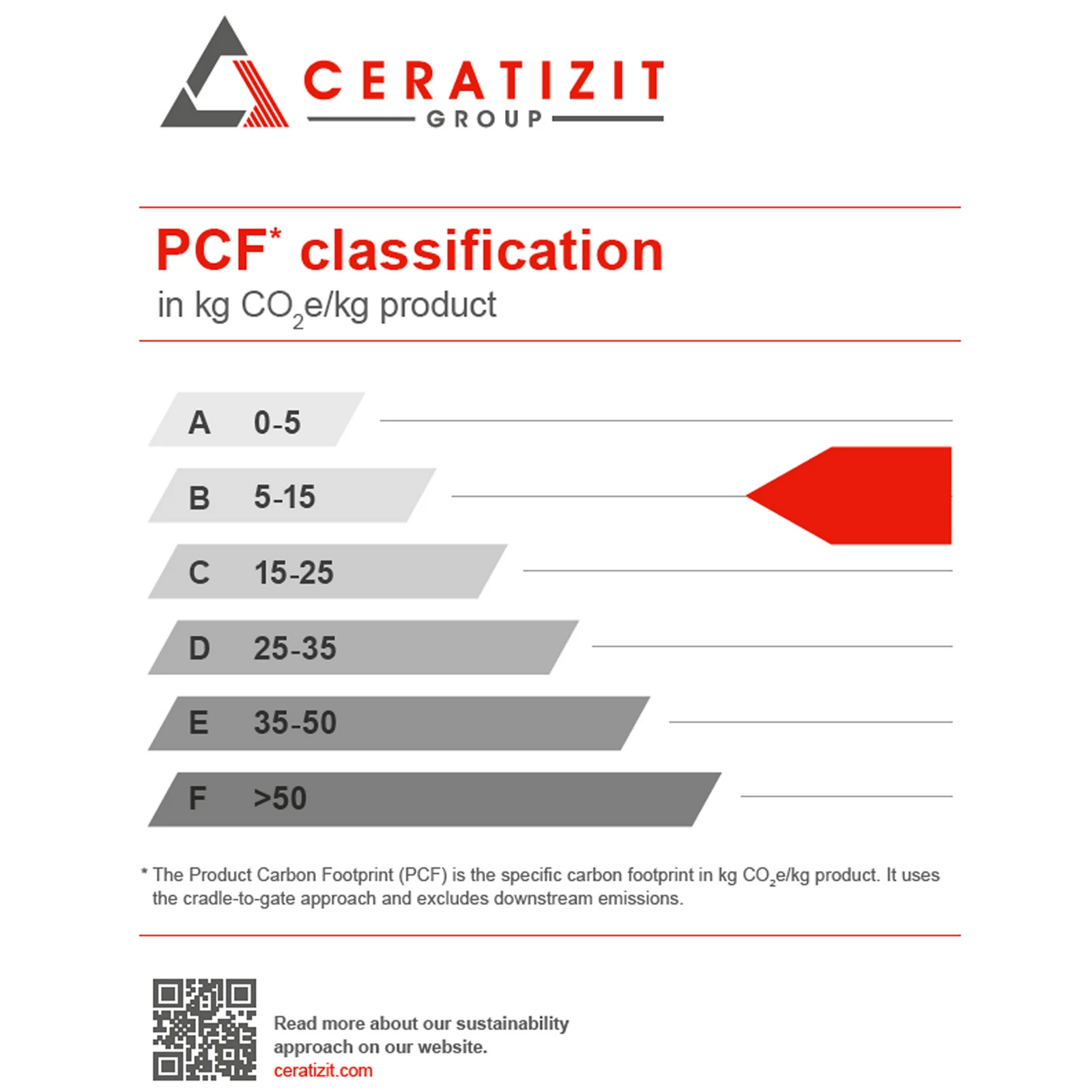

Product Carbon Footprint

Our goal is to establish a common standard on the market for calculating and classifying the carbon footprint of cutting tools, hard material solutions and tungsten carbide powders.

The constant innovation of materials and applications helps us and our customers to create a large number of machines, tools, applications, and consumer goods which shape our immediate environment and are part of our everyday life.

Our goal is to establish a common standard on the market for calculating and classifying the carbon footprint of cutting tools, hard material solutions and tungsten carbide powders.