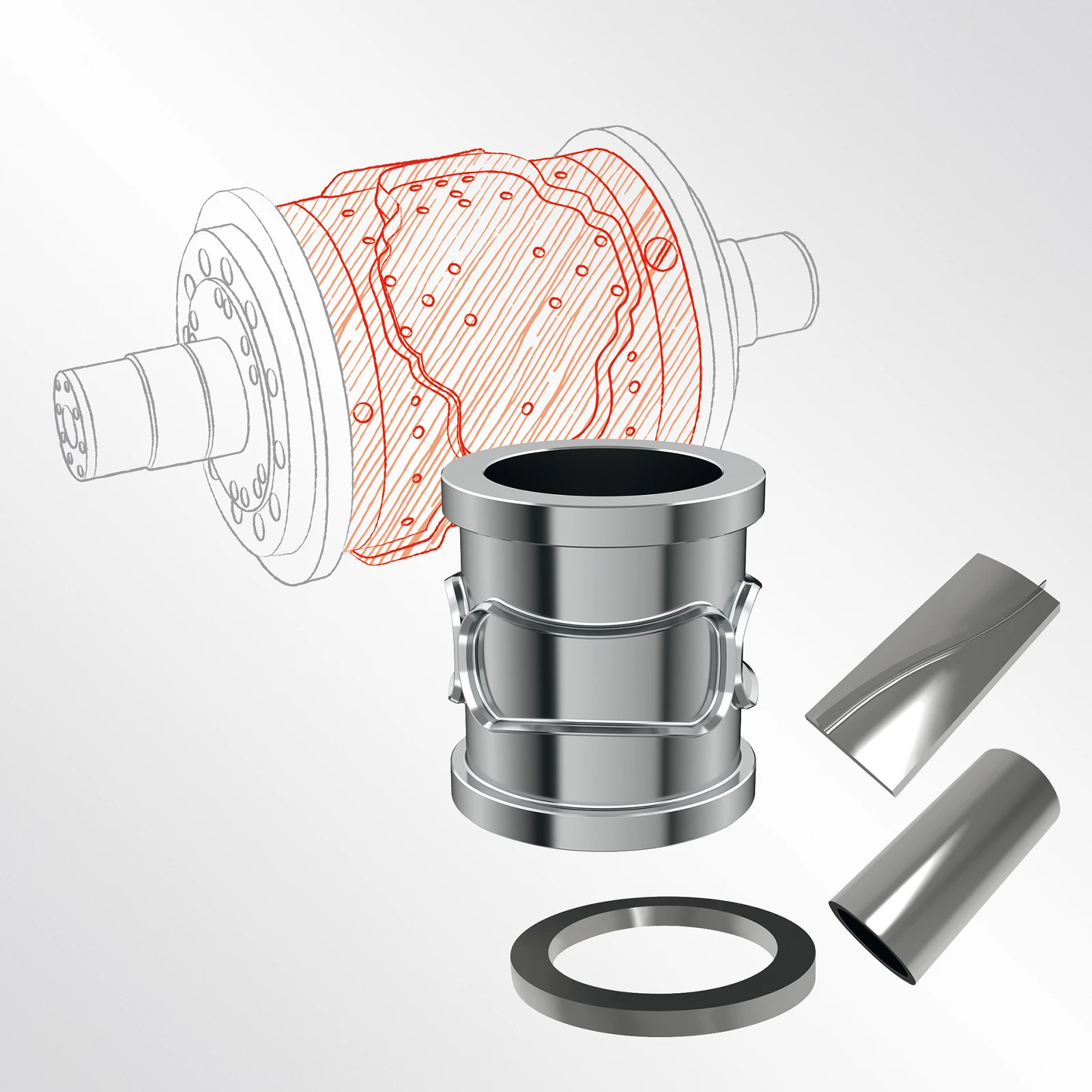

Rotary cutting dies for the most demanding requirements

Sophistication as a standard

Your wish is our guideline: you make your model available, and CERATIZIT will deliver – always under the premise of strict confidentiality! At company headquarters in Mamer, Luxembourg, our experts will create your rotary cutter blanks with up to 20 mm cutting height, which can be reground. Our production line allows for diameters up to 610 mm and heights up to 500 mm. Internationally renowned brands benefit from customer-specific solutions delivered within only a few weeks.