Efficiency. Precision. Process security.

High speed with long service life

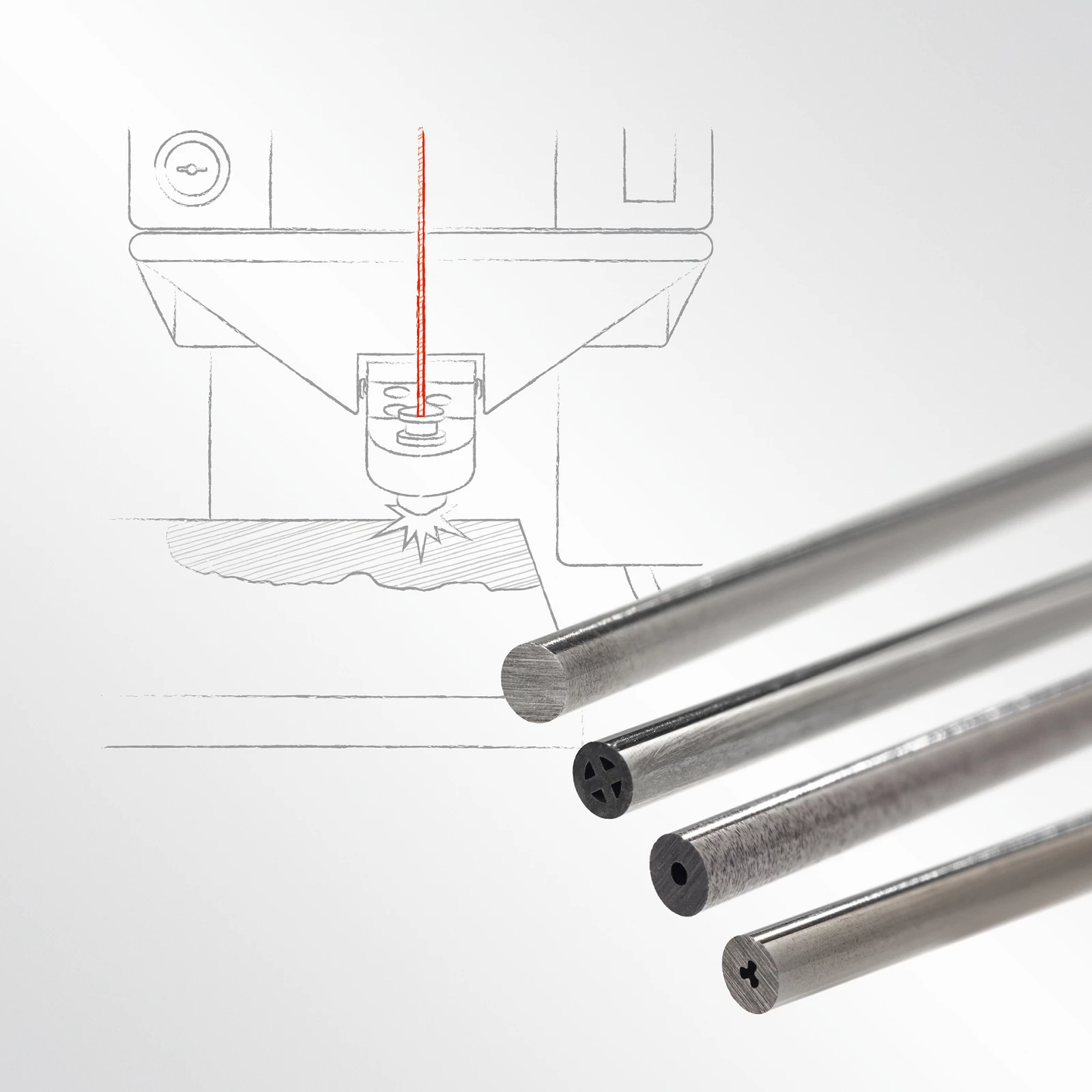

Our erosion material is substantially more resistant against abrasive wear than conventional electrodes made from copper/brass. Therefore, the consumption rate of the contact material is lowered and, in turn, the tool life is lengthened enabling higher possible feed rates.