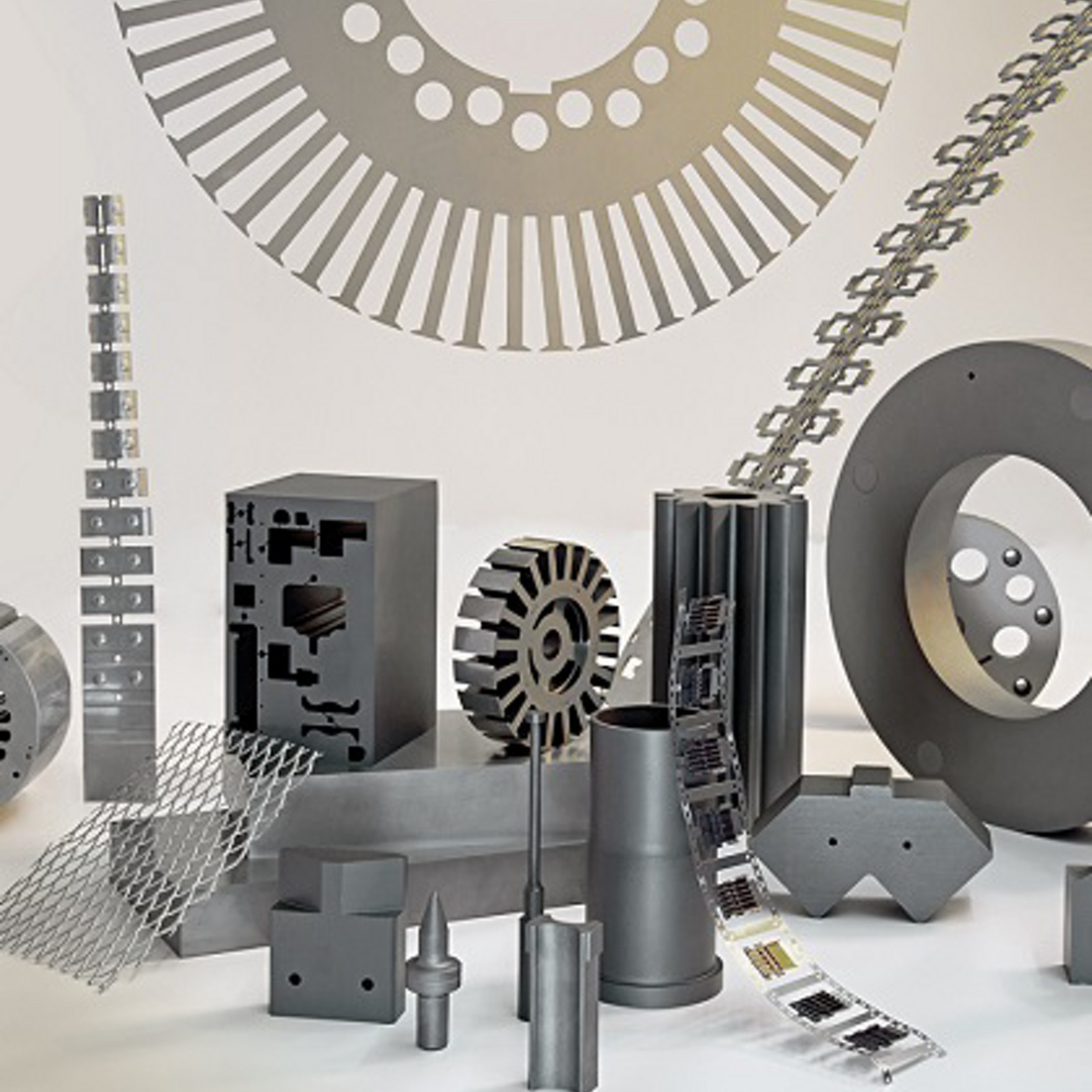

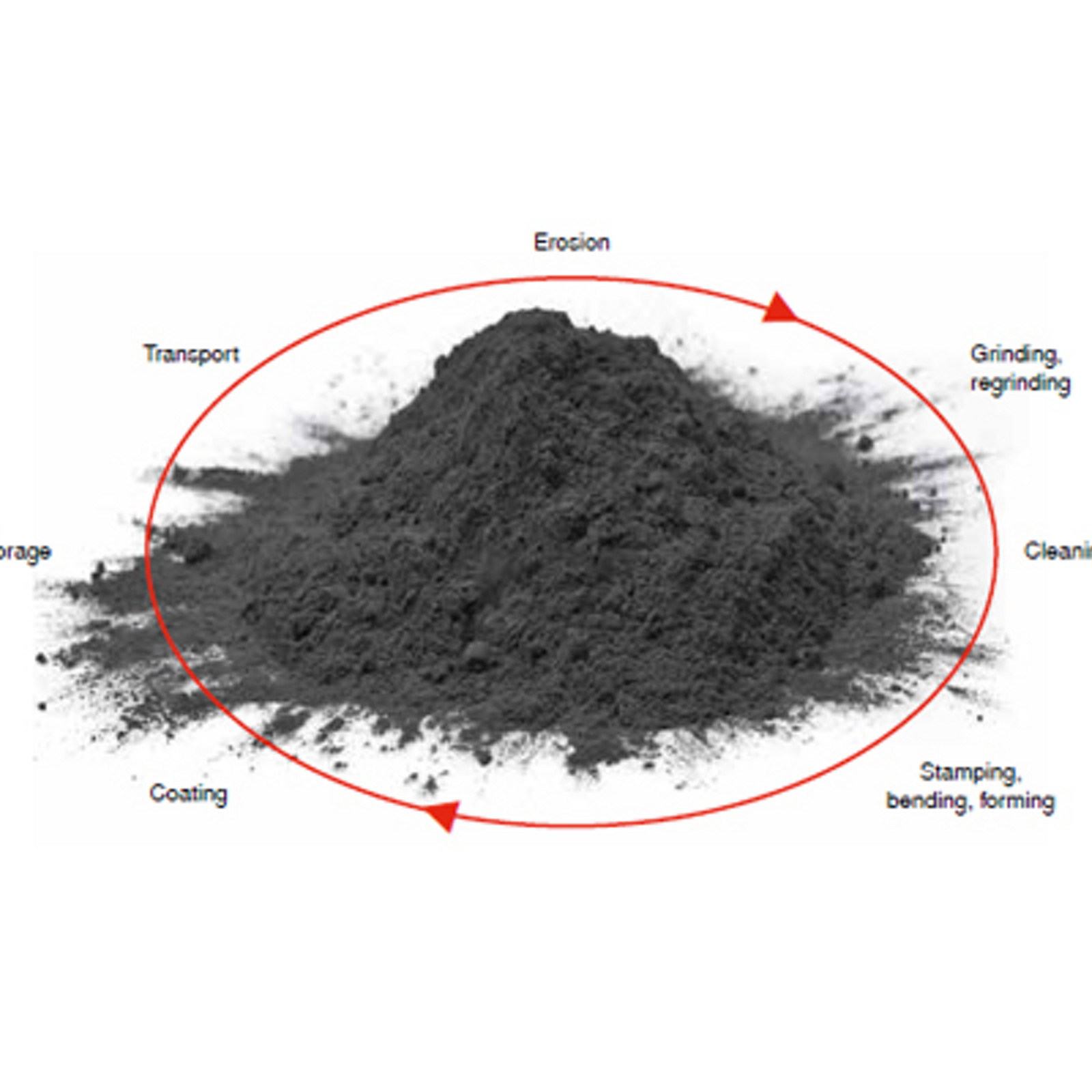

What our carbides are used for

Tool and die construction places carbides under extreme stress. Our carbide grades are tailored to match the many different applications. The wide range of grades we offer confirms the technological lead that, in combination with our long-standing experience in powder metallurgy, guarantees maximum quality and consistency. Our technological lead is the basis for your success.

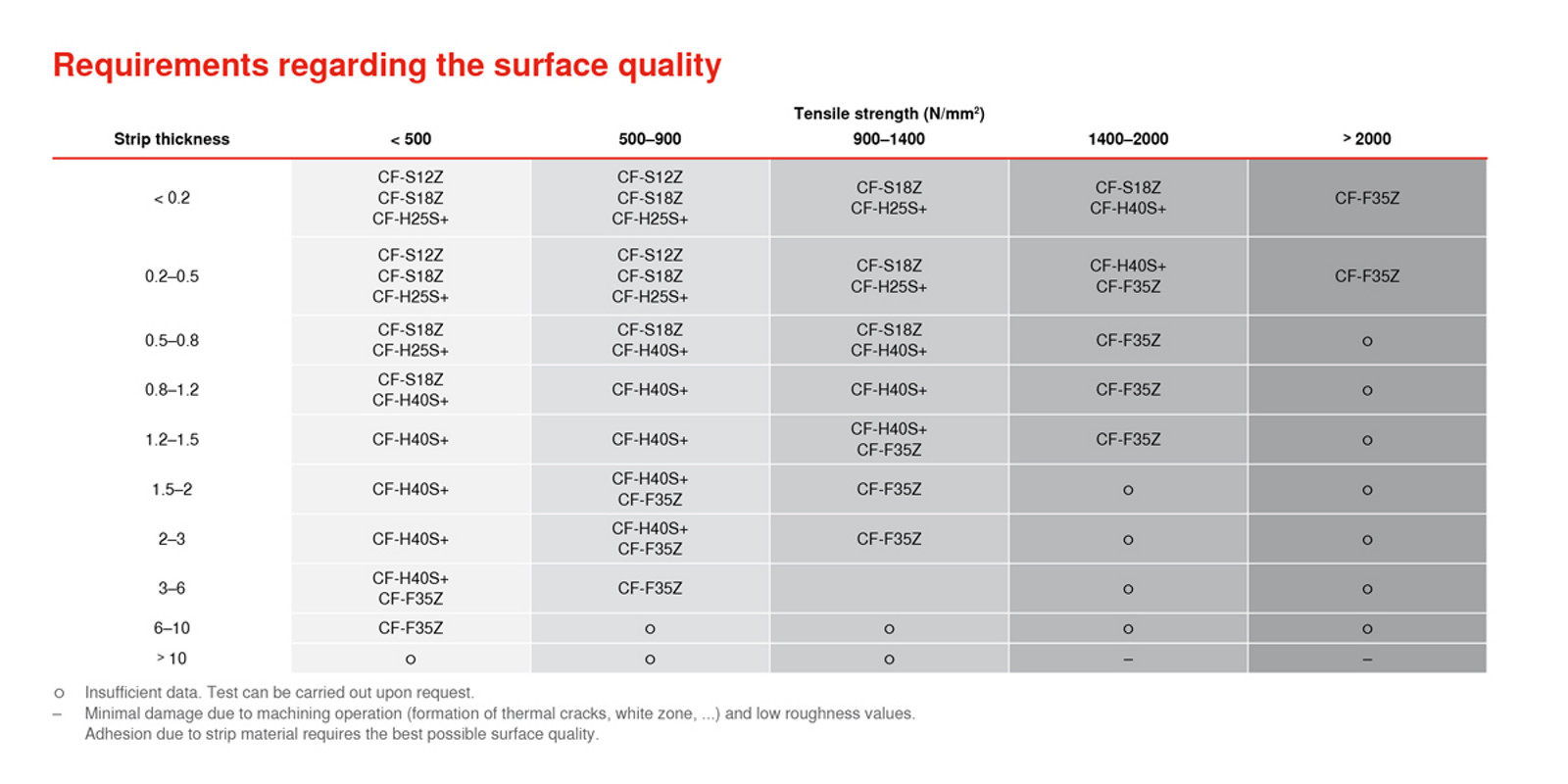

Corrosion-resistant grades

CF grades exhibit excellent corrosion resistance combined with the mechanical and physical properties required in the tool and die industry.

The following table offers a good basis for choosing the right grade. Further influencing factors such as the composition of the strip material, cutting gap, lubrication, geometry of the active parts and the structure of the tools should be taken into account in order to select the optimal grade.