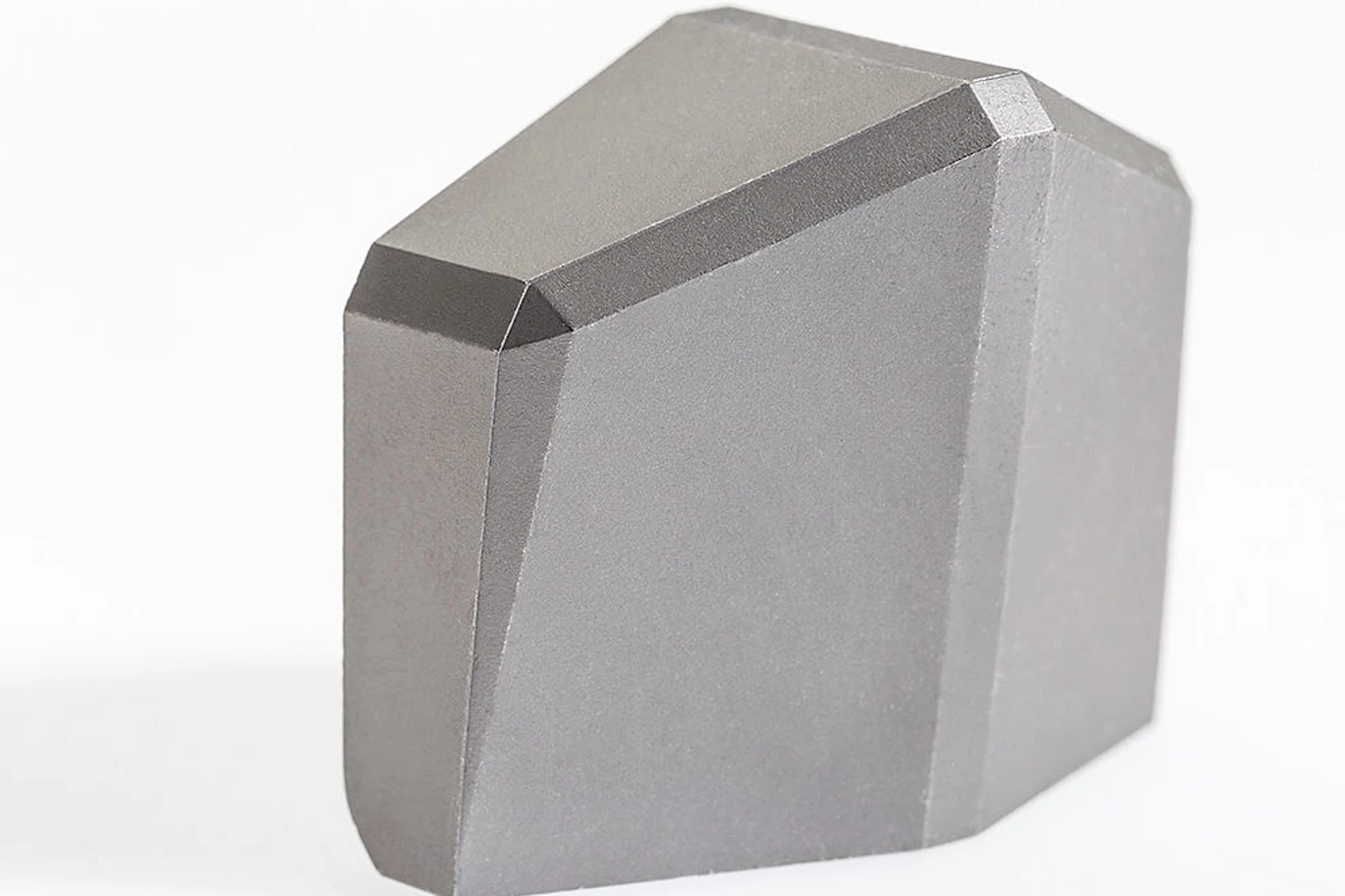

What is cemented carbide?

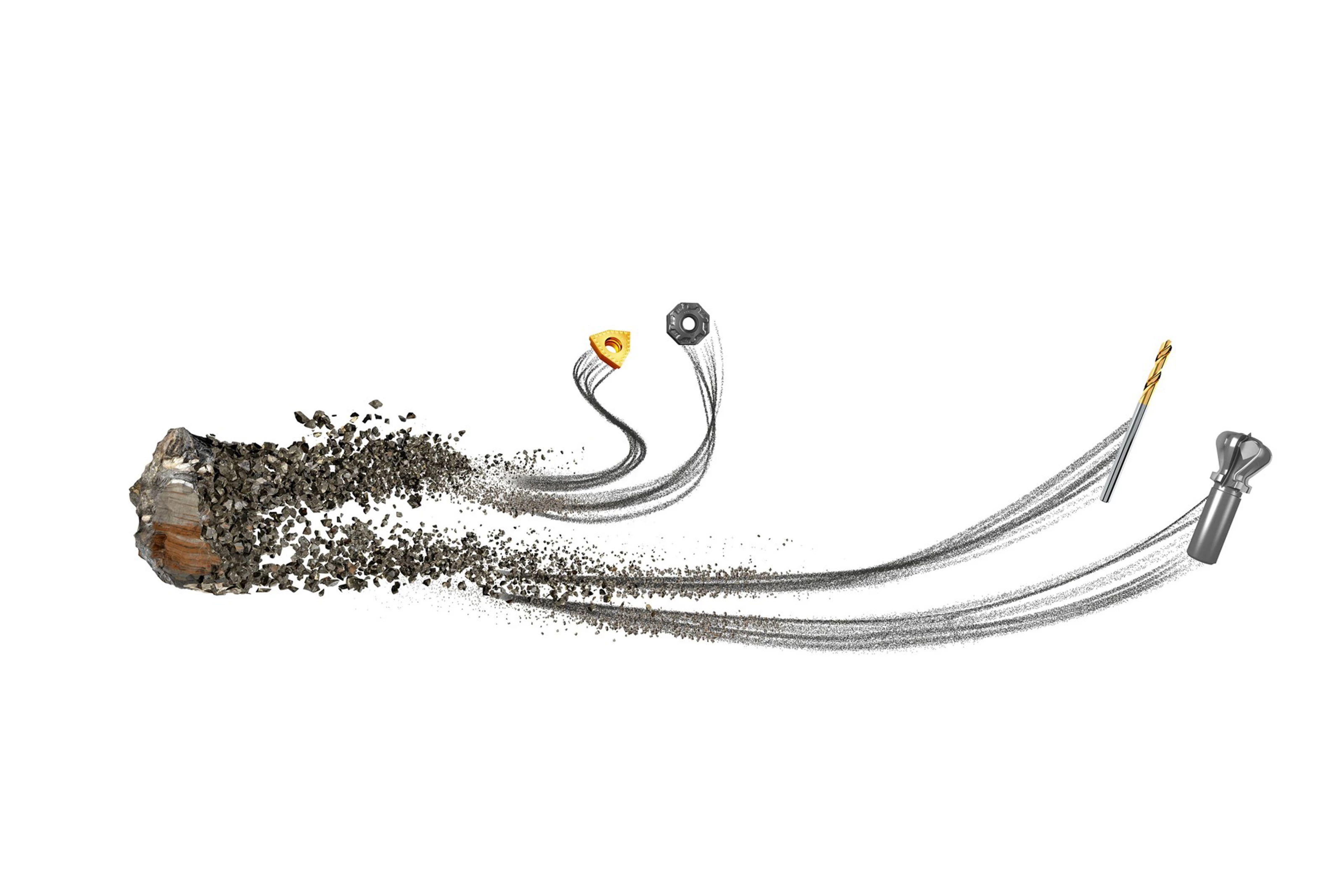

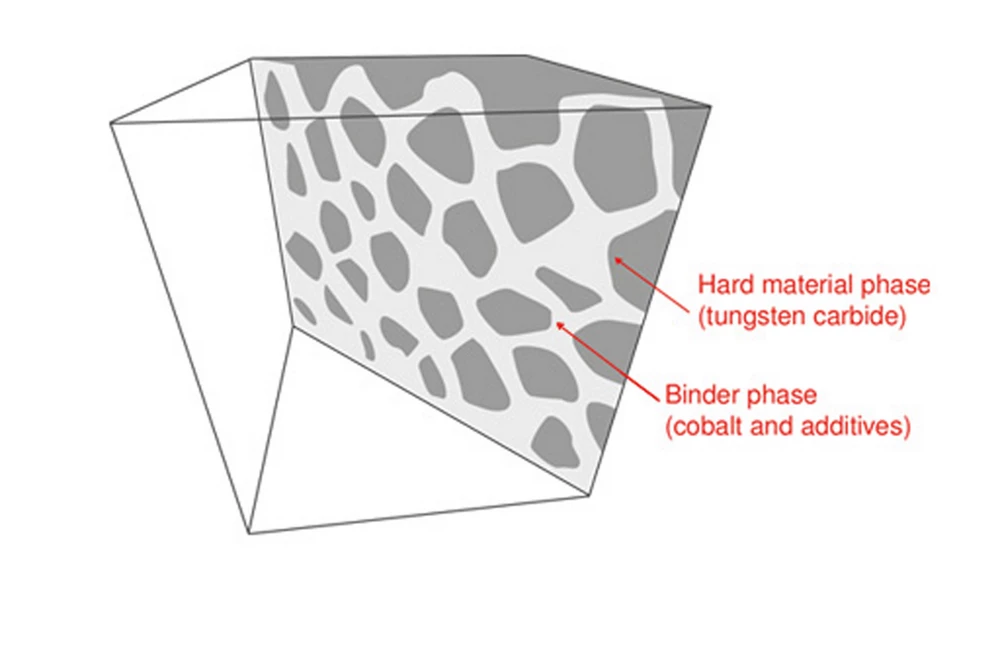

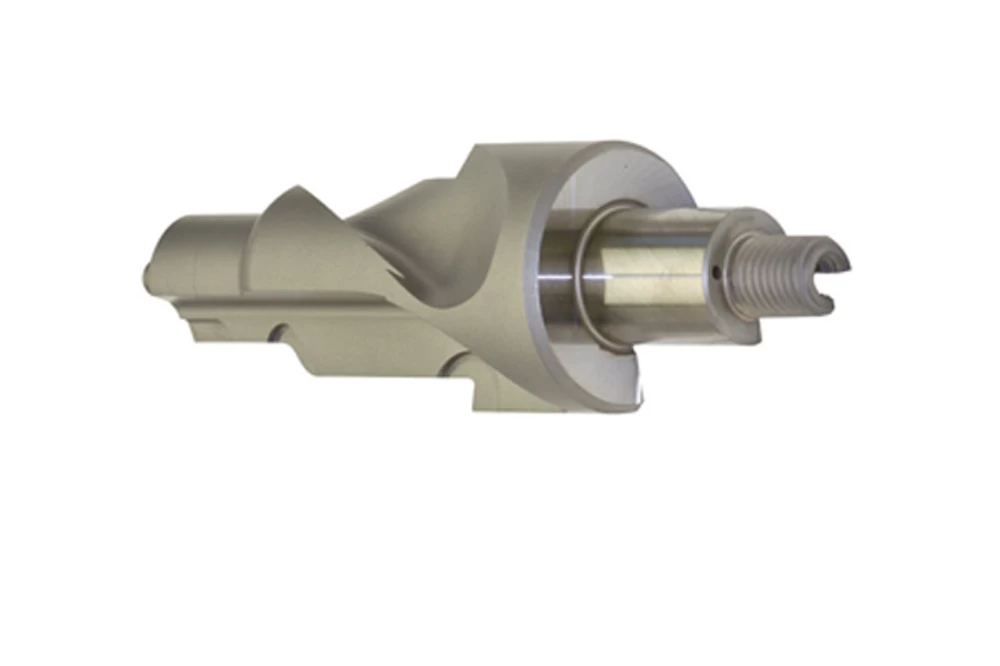

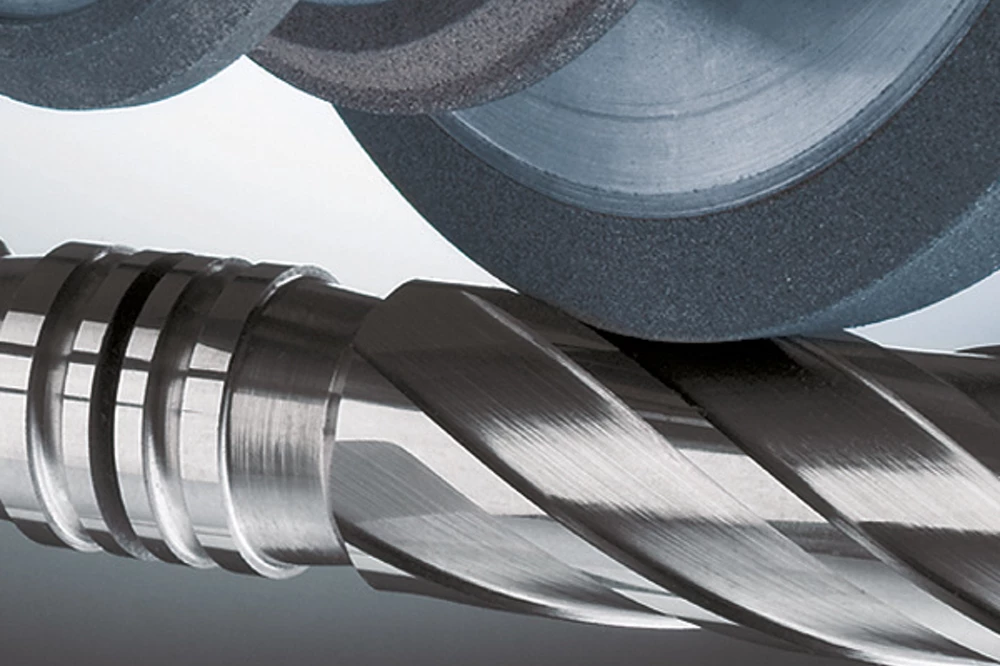

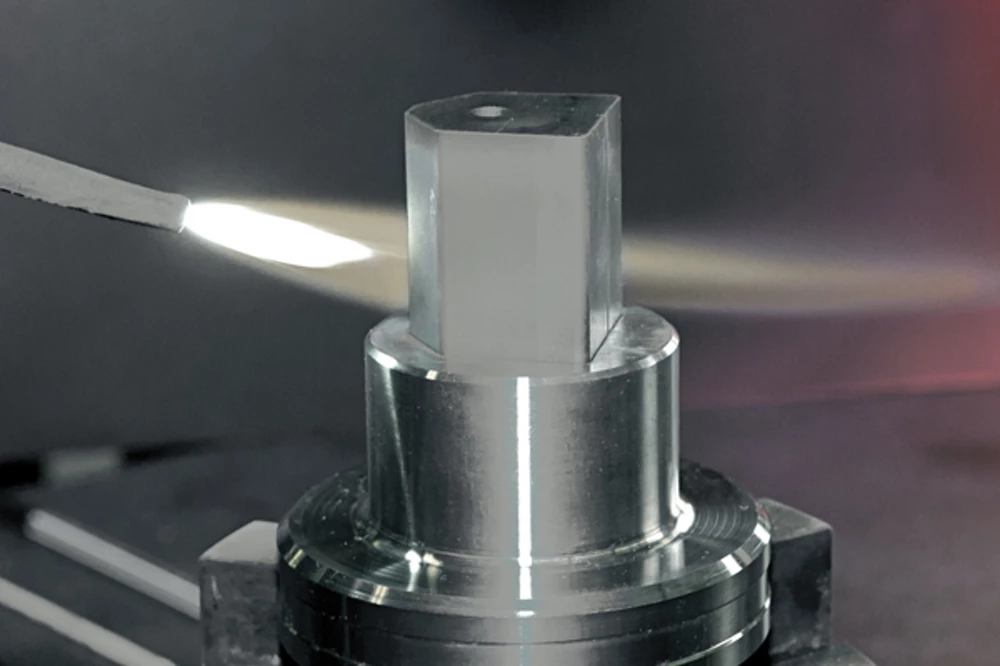

Cemented carbide is a composite consisting of a hard material and a very tough binder metal. The material is extremely hard, characterised by high wear resistance and high hot hardness. It is used wherever tools or components are exposed to high wear, as is the case when cutting hard materials. Carbide improves the quality of tools and components, gives them a longer service life and ensures that processes are safe and reliable.