Contact

Do you have any questions or a special request? Get in touch with us, we are here for you.

Contact Form

Do you have any questions or a special request? Get in touch with us, we are here for you.

Contact Form

Whether you're looking for a sales subsidiary, one of our production sites or a local dealer, find your point of contact close by on the map.

Map

For over 100 years, we have been developing and producing sophisticated hard material cutting and wear protection solutions. Read more about our history and innovation & technology.

Read more

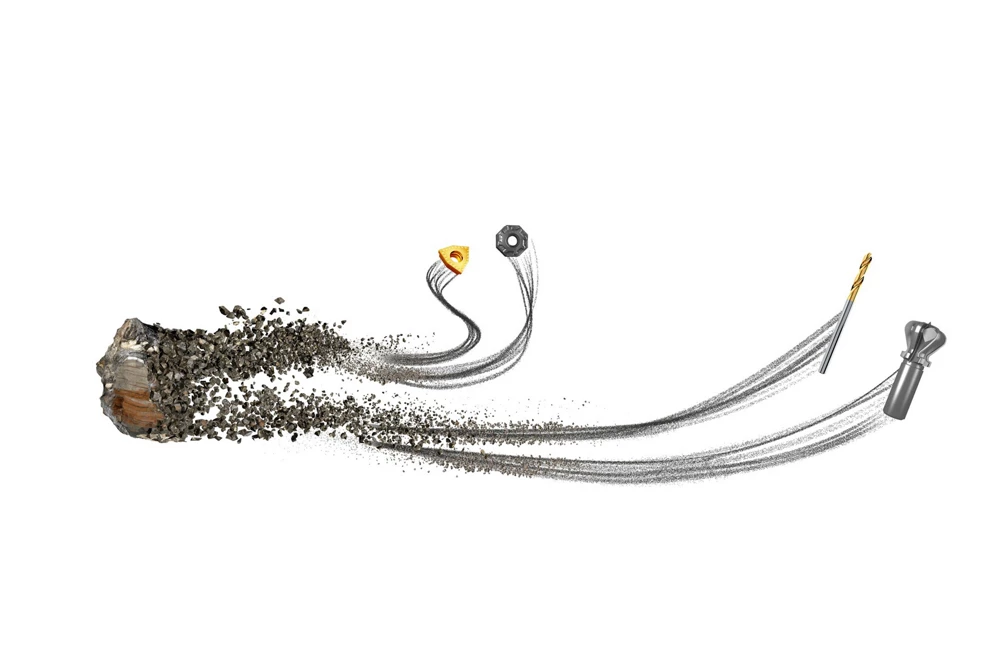

CERATIZIT manages the entire production process chain of cemented carbide and cemented carbide components. Lean more about the materials.

Read more

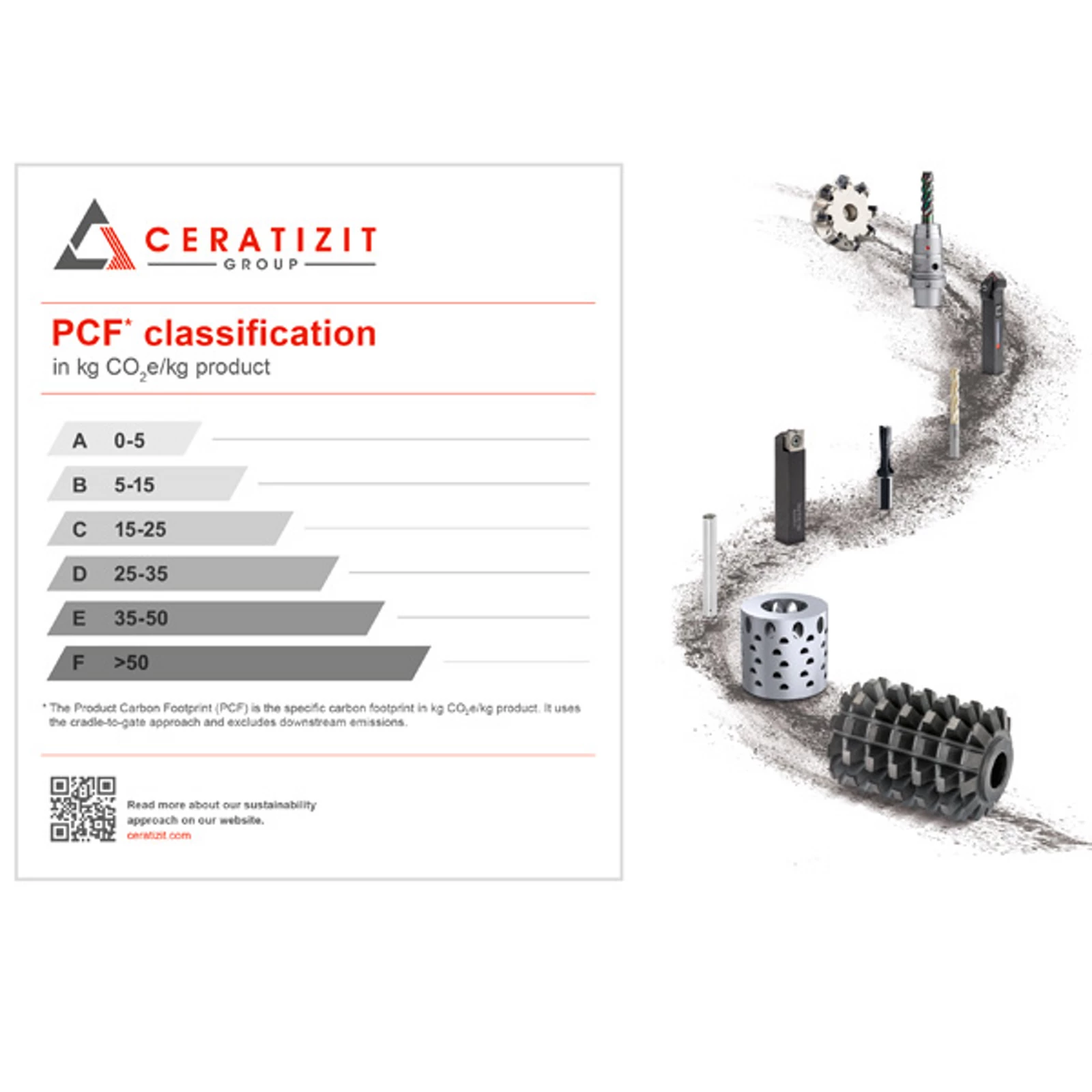

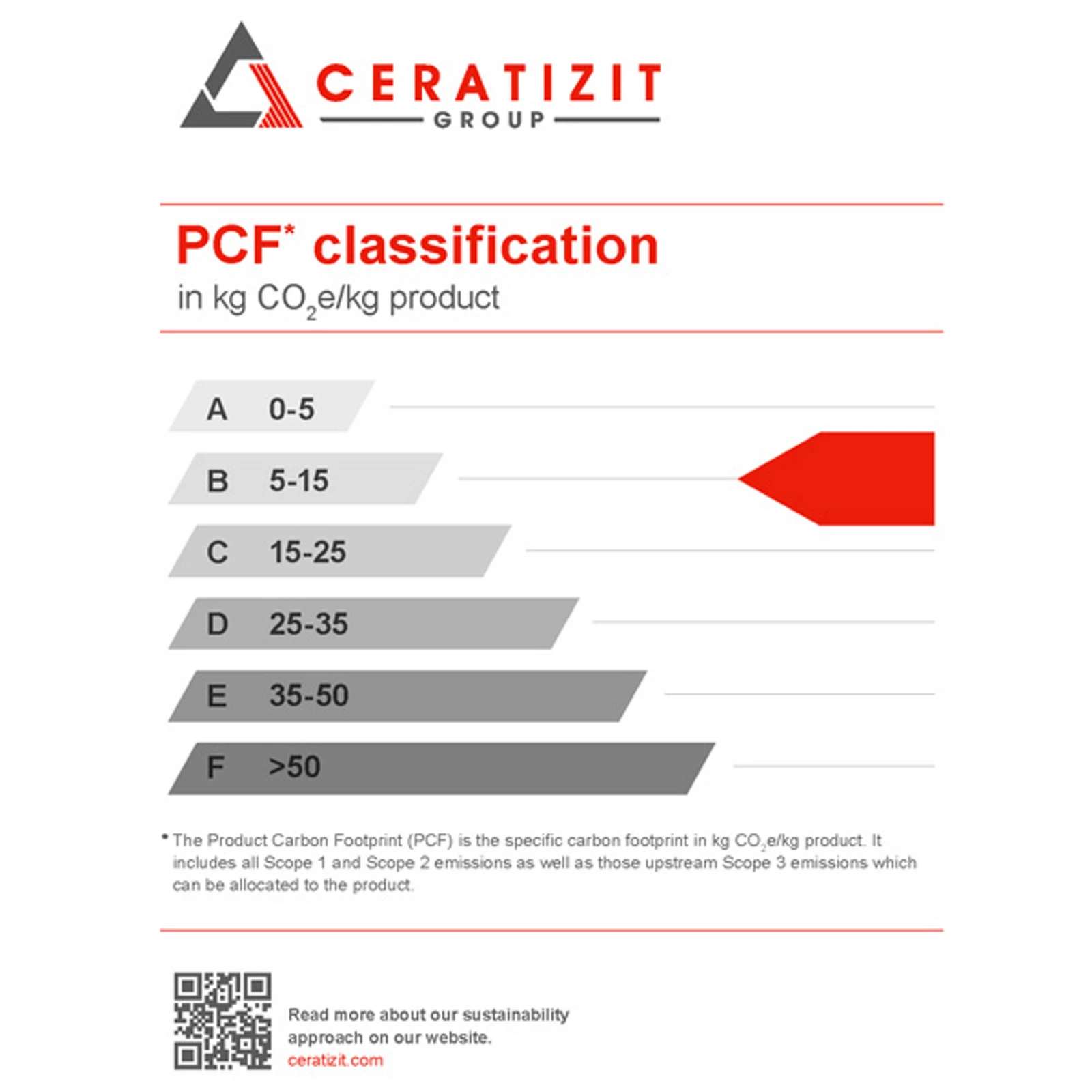

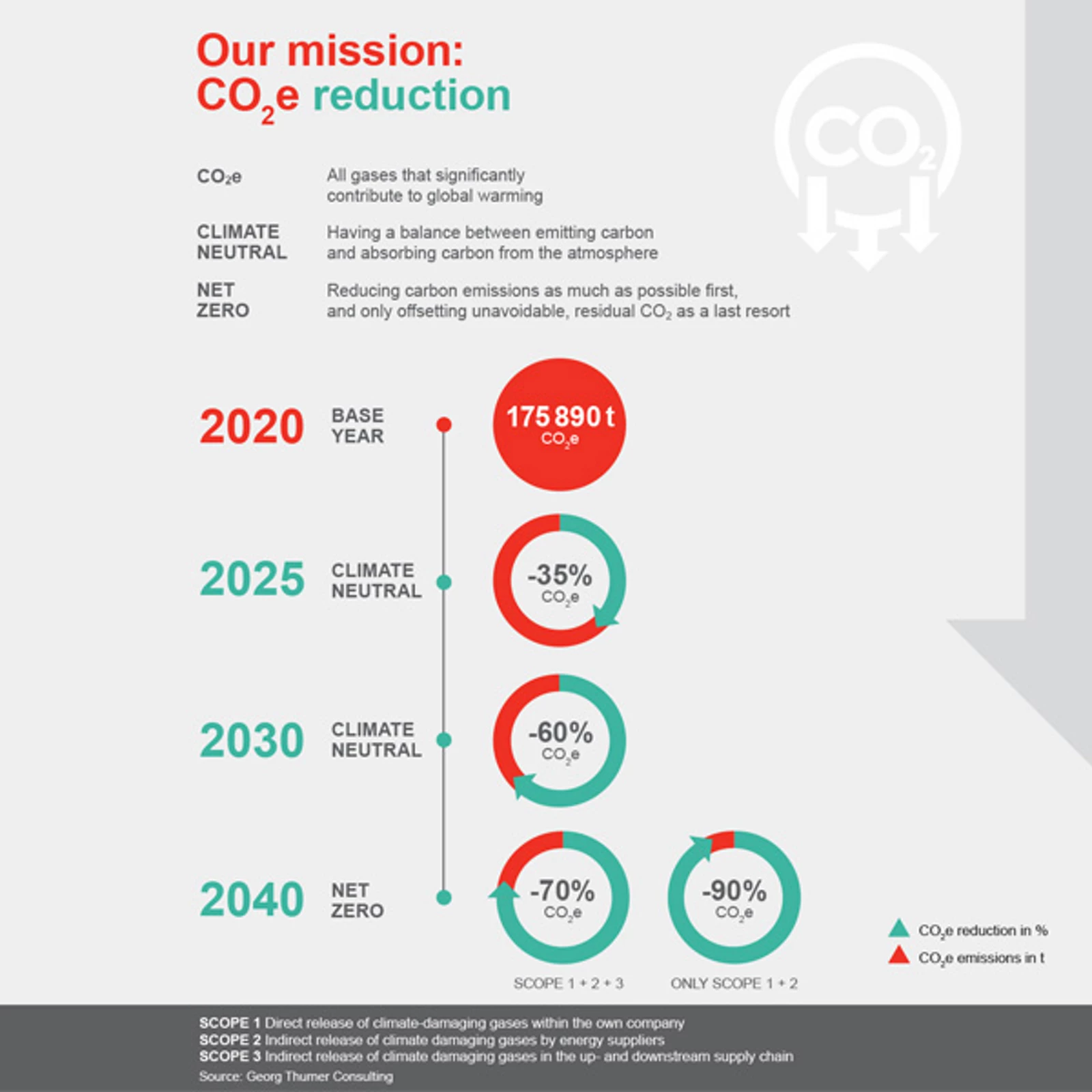

At CERATIZIT Group, we strongly emphasize sustainability and the responsible treatment of the environment. Read more about safety, quality, code of conduct or environment & resources.

Read more

By promoting a strong work culture which is based on our values, we aim to create a working atmosphere people can identify with, where we trust and support each other and commit ourselves with all our strength to a common goal.

Read more

Save the date! Meet us at a trade show or career event. Here you will find all the latest dates where you can meet with us.

Event Calendar

Get insights about the CERATIZIT Group and the people behind. Discover first-hand knowledge from our experts and get insider perspectives on cemented carbide and its applications. Always in focus: sustainability.

Read more

with us on the path to victory: the CERATIZIT-WNT PRO CYCLING TEAM

Read more

When CERATIZIT employees have creative ideas, in most cases innovative tooling solutions are developed for our customers. When CERATIZIT employees are musicians in their spare time, sometimes rock anthems are created.

Read more

220 CERATIZIT employees supported their CERATIZIT-WNT PRO CYCLING TEAM at the first ‘Tour de France Femmes avec Zwift’

Read more

The Tour de France Femme is the perfect occasion to showcase our entire scope of products. Why? As the tour winds its way through many of the landscapes our solutions are used in, we can shine a light on all the different types of agricultural tillage and soil that play a significant role.

Read moreBy recycling secondary materials, CERATIZIT also limits the consequences of intensive mining, such as air, water and soil pollution, and helps check the excessive use of energy.